|

| The backers are behind the top, center shelf and the middle, right shelf. |

One of the things that is kind of a fundamental way in which I approach most of my decorative house projects is doing what I can to make them un-doable. Obviously that's not always feasible - like with a tile back splash - but if I can use nails instead of construction adhesive with a good result, that's what I'm going to do. And if I can use screws instead of nails, then I'll to that if it'll keep the look right. That is how I approached this project. Someday we'll have our dream library in the next room and just take this less-than-ideal-for-us unit down, so not having weird rectangles of quilting cotton attached the wall is important for the future.

We were lucky that I had most of what was needed to make the backers on hand already:

THE BASIC MATERIALS

Bark print quilters cotton fabric

Fusible interfacing (I had enough for only part of the project)

Thread

Polypropylene sheets (you could use thin plywood, masonite, foam core, even strong cardboard)

Duct tape

TOOLS

Measuring tape & ruled straight edge

Level

Utility knife

Rotary cutter & scissors

Pencil

Sewing machine

Calculator

Small wire nails

OPTIONAL MATERIALS

Spray adhesive

Metal eyelets

Base shoe or quarter round moulding

House paint

First steps

1. Measure the back of your shelf in both directions. I sure hope yours is square - as in the angles are all 90 degrees, because everything is level and plumb - because it's hard to cut your backer if it's not. Mine was not and my backers are not quite right because of it. Which means I don't know how exactly to help you get it right, but I would recommend starting with something inexpensive/free and easy to get a hold of like cardboard or paperboard to get it just right before cutting into a more expensive backer material.

|

| Here are the fingerprinted and lint-coated scraps. Pretty impressive photo, eh? |

That said, use cardboard if you think it will maintain it's integrity through the process. Just be sure your material is strong enough to hold its shape while being flexible enough to get into place and that you have a way to cut that material.

|

| See how I had to make sure my backer was flexible to get around this? The front opening is smaller than the back surface. |

2. One you've got the size just where you want it - whether that is just-right or not - then cut your backer. Go ahead and dry fit it just to be certain it's right.

3. Press and cut your fabric with enough extra to wrap around your backer and at least an inch on the back. I did 1.25 - 2 inches on mine. Cut your interfacing just a bit smaller than your fabric, then follow the directions for that interfacing to fuse it to the back side of your fabric.

For the long backer, I had to sew together a few pieces of fabric to get it wide enough and that is what I used my calculator for. Had my print not been directional, I probably could have gotten it without that. I also had to piece together my polypropylene backing, because my sheets are pre-cut to 24" squares.

Next...

4. Lay your fabric wrong side up on a clean, level work surface that is big enough to fit the whole backer board on it. I used the guest room floor. Then center your backer board on that, back side up. Make sure you have the top of your backer matching the top of your fabric if you have a direction fabric. You can see I wrote on my the backside of my backer just to make it easy to keep this straight.

If you're working with difficult material, large piece, or are just nervous about keeping it all aligned, you might want to use spray adhesive on your backer then lay it on your fabric. Be sure to smooth over the surface so the adhesive makes contact all over. Obviously, test on scraps to be sure it won't bleed through your interfaced fabric, etc. Maybe double-sided tape would work, too, I haven't tried that.

5. Pre-cut/tear several strips of duct tape into 5-6" strips. You may have to do this a few times as you work your way around.

6. At the center top, fold over our fabric and tape it down. You want an nice crease, but you don't want to move the material around. If you have used the spray adhesive this shouldn't be a problem. Then do the opposite side. Then work your way, evenly down the left and right sides, alternating top and bottom.

I did my corners with one of the standard miter methods.

7. For the sides, start in the center and work your way to either end. Because my sides were fairly short, I did one whole side before doing the other. It ain't pretty, but it doesn't show and it's just for us.

Finally...

8. Flip it over and admire your work!

Installing that beautiful beast:

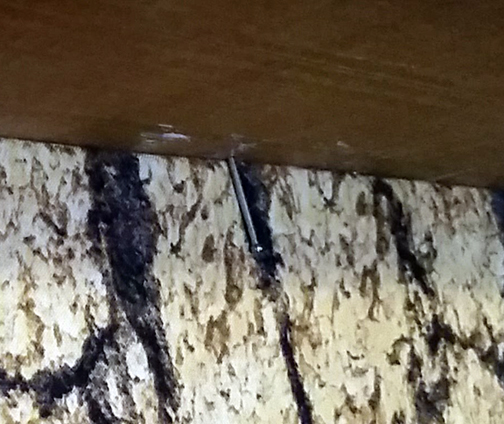

9. Have your hammer and wire nails ready, then put your backer in place. You might be able to use double sided tape for this, too, depending on how heavy your covered backer is. For mine I tacked tiny wire nails into the bookshelf about 1/4-1/3 of the way in, then bend them towards the wall with my thumb. Sort of like those metal tabs in the back of some photo frames. They are really hard to see so it works fine. I was originally going to paint them brown, but didn't have to.

Another option would be to add a small moulding piece. For the backer on the right end of the unit, I ended up using a bit of leftover base shoe from our kitchen island project. This was not so much to hold it in place as it was to cover where I messed up cutting my backer. LEARN FROM MY MISTAKES and dry fit, dry fit, dry fit!

|

| I did have the foresight to paint the wall a color closer to the fabric, at least. At least the closest I could come with paint on hand. |

And in actuality, that piece is held in place by nails in its own way.

Here is where the optional eyelet came into play. I knew I was going to display these sentimental pieces in there, so cut holes in my backer before covering it with the fabric, then after it was installed gently cut the fabric over the holes, and added the eyelets with a bit of glue. Just to keep the fabric from doing weird things, even though the interfacing would almost assuredly take care of that. It was a craft-geek moment, what can I say? Soooooo, that backer is essentially hung on those nails like an frame or other decoration or art would hang on a wall. The moulding is mostly to cover the gap and I didn't even nail it down... it was stable enough without doing so and this would be easier to undo (see second paragraph).

|

| A little dab of base shoe will do ya'. |